Dampers

It is part of a rubber and metal machinery that serves to resiliently mount moving parts. They are often used in the automotive industry to mount axles, engine, stabilizers, gearboxes and wherever different movements are needed to be dampen. Dampers enable flexible fitting, shock absorption, vertical and transverse vibration isolation, and noise insulation. Dampers work without lubrication and other maintenance.

|

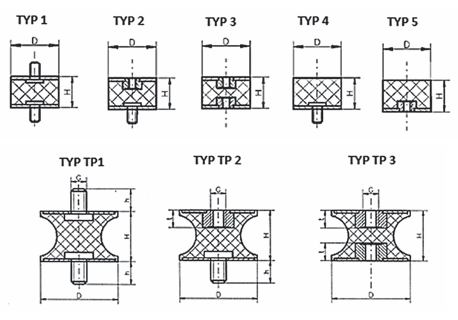

Standard dampers Standard dampers consist of a rubber compound between two metal round plates. Everything is connected by vulcanization. Dampers may be provided with screws, threads or a combination of both. These dampers are well resistant to pressure and shear loads. Standard dampers are divided into 8 basic types:

|

Nonstandard dampers Non-standard dampers include bushings, silent blocks, puffers, etc. Each of these types of dampers has its own specific features and areas of use.

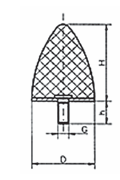

Conical Puffers are particularly suitable as stops. They are designed for high dynamic load. The shape of the silentblock also increases its service life. Conical silentblocks should also be better at cushioning noise than standard. These silentblocks are commonly made from natural rubber. It is important that the metal part of the silentblock is attached to the plate to which the silentblock is clamped.

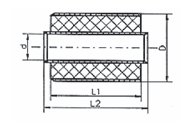

Bushings it is a cylindrical silentblock capable of absorbing axial, radial and twisting movements. They are maintenance-free, prevent noise transmission and are also usable as a connecting element eg in drive units. Typical applications are flexible joints on vibrating machines or bearing blocks for shafts, axles as well as gear and clutch control. |

Heavy duty dampers Heavy duty dampers - these dampers are made of natural rubber and chrome without galvanizing (for optimum corrosion protection). Low-frequency noise is also well insulated. Possible applications include combustion engines, electric motors, pumps, compressors and machine tools. They are also used in marine engineering. The rugged design resists high pressures and prevents dampers movements in both vertical and horizontal directions. The shape of the bell also prevents contact of the rubber with dripping media (oils, etc.).

Leveling feet These silent blocks combine a low compact design with good insulating capabilities and stability. They are made up of two metal parts and vulcanized rubber. The leveling feet are made of NBR-resistant rubber. Embedded technology allows for better balancing. Thanks to its construction, it is not necessary to anchor the foot to the support surface. Make sure that the surface of the machine is parallel to the support surface of the foot and everything is smooth and clean.

Pipe Holders Pipe holders are also anchor and anti-vibration elements. They are made of two parts made of metal plate and molded rubber between which the pipe is secured and withdrawn by screws.

Polyurethane Buffers Used to stop the falling counterweight. They are made especially of polyurethane. It is mainly divided into buffers that accumulate the kinetic energy of the counterweight and the buffers that distort the kinetic energy of the counterweight. They are maintenance-free, they have to be inspected visually for routine inspections. They are resistant to oils, gasoline, ozone. They should not be in constant contact with water.